Hoga Industry Co., Ltd. was established in 1976 in Da’An District, Taichung City, Taiwan. We are one of the biggest professional manufacturers specializing in the production of excellent quality engine valves, valve guides, and valve seats for over 45 years. We offer a comprehensive range of products suitable for all kinds of petrol and diesel engines such as motorcycles, passenger cars, trucks, heavy-duty equipment, and marine engines.

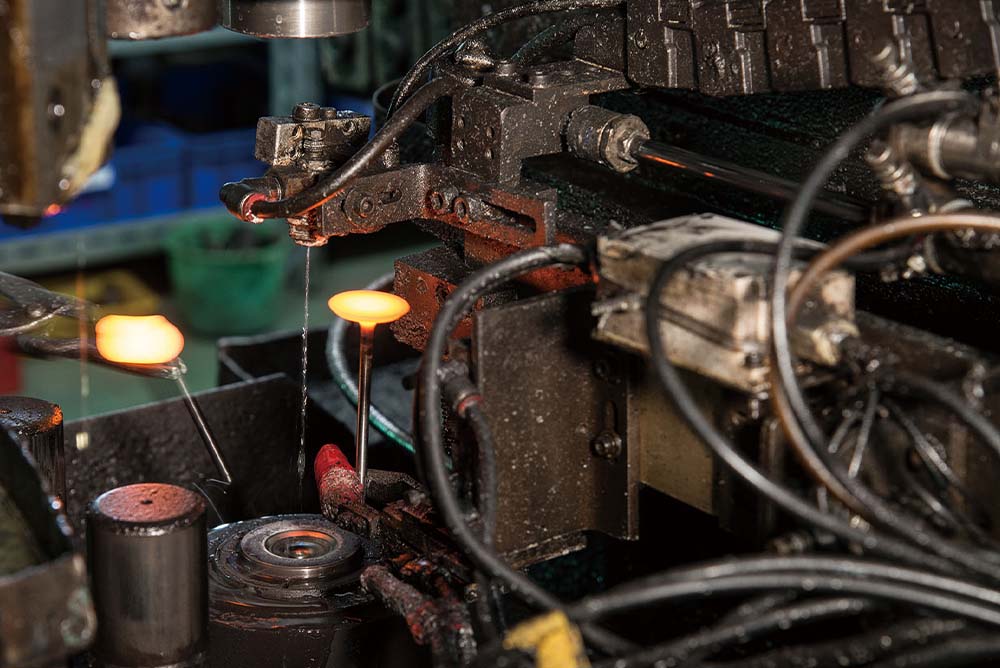

We proudly own precision production equipment and advanced manufacturing technology to meet customers’ strictest demands. In order to attain accurate dimensions, we focus on every detail of the production process and establish strict quality control by conforming to ISO/IATF16949. This principle is applied to cutting, forging, turning, welding, grinding, appearance checking, and 100% ultrasonic inspection up to the final packing. Each stage of the process is designed to achieve perfection and therefore enables us to bring out the highest quality products as well as to achieve punctual delivery. Our company is committed to delivering customers’ satisfaction and needs in both OEM and aftermarket.

Since

Patents

Employees

Sha-Lu plant was established.

Production of engine valves.

Became one of the O.E.M. qualified supplier to domestic DAIHATSU 、PEUGEOT.

Became one of the O.E.M. qualified supplier to domestic local Motor- scooter factories.

Cooperation with Chung-Shan Institute of Science & Technology, TJING LING INTL. Welding of Taiwan University, National Chen-Kung University and Feng Chia University for the production of engine parts, R&D of production technology.

ISO-9002 certified by the BUREAU of Merchandise & Inspection.

In order to strengthen & developing on the Europe and America market, cooperated with HOTA Industry and reorganized to established HOGA Industry CO,. Ltd.

Passed of ISO-9001/ Ver. 2000 quality certified system. Accomplished of develops & produce of Engine valve, Valve Guide & Valve Seat Inserts for marine application.

Accomplished & develops Largest size of Engine valve: H/D=112m/m, S/D= 24.9 m/m, T/L=570 m/m

In order to upgrade parts’ quality by using Ultrasonic flaw detector tester to prevent any defective parts to be released out.

The key to using TIP welding machine, welding area of more than 95% after welding process. Enhance the accuracy of Q/C inspection skill by using “Optical Comparator “imports from Japan.

Completed & develops Valve Seat Inserts surface with special treatment by Thermal Spray process. Also, other related parts for Marines’ application.

Accomplished & develops Largest size of Valve guide: Overall Length=279 m/m, I/D= 71.03 m/m, O/D= 102.035 m/m

Sourcing for new valve steel supplier in Italy, to decreasing / dispersal risk of material procurement.

To improve & enhance product quality & concentricity, imports of “New concentricity gauge”.

To enhance forging capacity, introducing “Vertical two-seater electric heating up-setter with temperature display ” , ensuring that the heating temperature is stable.

sourcing for new valve steel supplier in Germany, to decreasing / dispersal risk of material procurement.

New factory finished, moved to the current location & starts of production run.

To better improve testing result of Hardness on raw material and inspection process to ensure the accuracy of the quality, Imported “New Rockwell hardness tester” HR-200,

Introducing new technology (Quench- Polish- Quench), referred to as “QPQ salt bath processing technology” significantly improve the hardness of the metal surface, thus increasing the wear resistance, corrosion resistance, is a new metal surface hardening technology; (NITRIDED) ion nitriding & gas nitriding excellent wear resistance, fatigue resistance, corrosion resistance at high temperature.

In order to meet customers’ requirement & self-improvement, imported new “Surface Roughness Inspection ” equipment.

Made a formal accreditation by the ASR, Hoga Industry had earn & passed ISO/TS16949 quality certification system,

This site uses Cookies to improve your browsing experience. we’ll assume you’re OK to continue. If you want to read more about this, please click PRIVACY thank you.